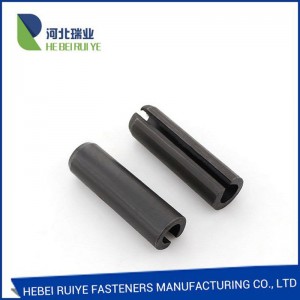

Retaining rings for shafts Black Oxide Coating Din471

Available Sizes: 8 mm to 400 mm

Standard Material: Carbon Spring Steel

Standard Finish: Phosphate and oil

Open these rings, pass them over the end of a shaft, and release to spring into the groove. Ring ID is measured with the ring uninstalled. Use retaining ring pliers (sold separately) to install and remove rings.

Spring steel rings are an economical choice with good strength. A black-phosphate finish is mildly corrosion resistant in dry environments. In wet environments, zinc yellow-chromate plated finishes have some corrosion resistance, and zinc-chromate plated finishes have good corrosion resistance.

Thrust load capacity, also known as PR, is based on using a shaft that is harder than the ring.

SURFACE FINISHES :Phosphates and oiled Blackened and oiled Manufacturer's choice

Version:Phosphated spring steel.

Bright stainless steel.Note:DIN 471 circlips are retaining rings mounted in a groove on a shaft OD. They withstand high axial forces between machine elements (e.g. bearings) and the groove in which the ring is mounted.Drawing reference:

Tapered section retaining rings decrease symmetrically from the center to the free ends, remaining circular when contracted or expanded within the limits of normal use. This assures contact with the groove along the entire periphery of the ring. These rings may be installed axially (horizontally along the center point of an axis) or radially (externally along the radius of a circle). Depending on the size of the ring in question, it may be manufactured in one of two ways:

- For smaller rings: using a Die and stamping on a Press from a coil of steel or copper

- For larger rings: wire forming, in which rectangular wire is coiled into the shape of the ring.

We have a large inventory of retaining rings in stock for immediate shipment to save you time and money.

Other Product