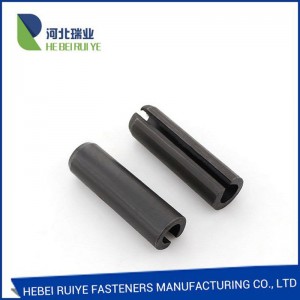

Spring Steel Phosphate External Snap Retaining Ring Washer DIn6799 manufacturer

Size:M8-M30

Samples: Samples is Free,

1.There is no MOQ,if the items are in stock.

2.Mixed orders and sample orders are also accepted

If any other questions,please email us or send your inquiry details in the bottom!

As we known as E-style rings, these rings have three prongs that make contact with the shaft and provide a wider shoulder than other external rings for a larger retaining surface. Use a side-mount retaining ring tool (sold separately) to push them into the groove from the side of the shaft. Ring OD is measured with the ring uninstalled.

Material: Spring steel

Hardness: 46÷54 HRC  460÷580 HV

460÷580 HV

Note:E-type circlips are pushed into a groove on a shaft. They are DIN 6799 standard elements and are designed for use on small shafts.

Circular push-on retaining rings may be installed in applications where there is no groove.

Retaining rings are typically made from carbon steel, stainless steel or beryllium copper and may feature a variety of finishes for aesthetics and corrosion protection depending on the type of environment in which they are used.

These rings are equipped with assembly holes and are typically fitted and dismantled using special pliers. It is important to use the appropriate pliers as designed for each single ring. Please refer to the pliers data chart for the correct pliers/ring combination. If rings are over-expanded, elastic deformation of rings can occur during assembly. This leads to very high bending stresses, so it is important to note:

During assembly, a ring should be expanded or closed only to the extent necessary to pass over the shaft or into the bore. The shaft and bore must be of the same nominal diameter as the ring.

Contact US: Skype/WhatsApp: +8618833059594 WeChat:+8618713913345

Application :Apply in the axial trough of the machine or equipment in order to avoid the axial movement of shaft parts